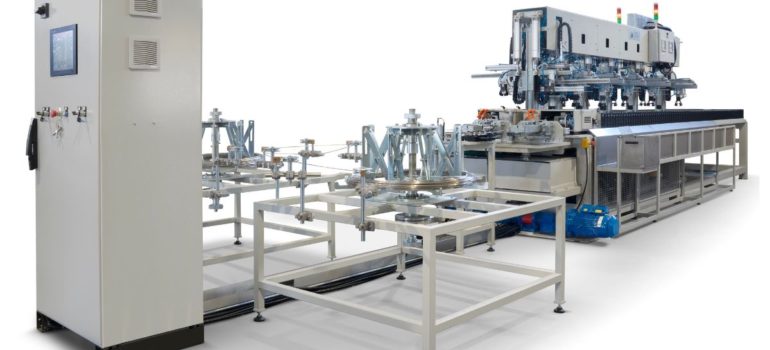

New double automatic drawing plant with cut of worked bars

Violi company always stands out in the field of tubes drawing!

Violi drawing method has been recognised as a revolutionary system since the 1990s, because it uses hydraulic forces instead of traditional pulling systems. Using these tube drawing technologies, customers can get a good hardness of the material and resistance to wear and this consequently guarantees an excellent workability of the product in machine tools. This method takes significant increase in productivity, with a considerable reduction in the metal used and thus in the processing waste. Starting from this system, Violi designs and produces fully automatic and customized systems for the tube industry. The company is thrilled to enter this world by developing fully automatic drawing systems, starting with the selection of bars and ending with their storage after drawing. The new double automatic drawing plant Violi, is born thanks to the research and development of Violi patented technologies and thanks to the fine tuning of machines listening to the needs of customers that, for production requirements, needed a drawing bench with separate and independent stations.

The plant is composed of indipendent unwinders with indepentent cutting units with clamps for Wire cutting. Unique structure with double independent drawing pull with the possibility of drawing different diameters and lengths. One exclusive system that allows the start of the drawing in a gradual manner thanks to the programming of power and speed. The ejection of tubes is automatic. They are deposited via pick places in adjacent side warehouses without interruption of the cycle. All movements are carried out safely using sensors, Photocells and metal barriers. All working data can be adjusted via the Touch Panel or by remote control. The logic of the plant, in addition to determining all processing parameters, has the possibility of entering recipes and being able to recall them as necessary.

Technical details change according to customer requirements.

For more information contact: marketing@violimacchine.it